This is a foamed product which achieves an ideal balance of flexibility, smoothness, heat insulation, and sealing. Various kinds of Softlon S, whose expansion ratio is from 5times to 40times, can be selected according to customer needs.

Features

The standard type with all the Softlon's basic functions.

Eco-friendly

Among resins for foam products, polyolefin is known to be environmentally friendly.

|

Chemical resistance

It isunsusceptible to chemi cals such as acid, alkali and organic solvents. thanks to its resistance to them.

|

Thermal plasticity

It has the features of being stable form at normal room temperature and getting soft so as to be easily molded. when heated.

|

Workability

It responds to various processing methods such as slicing, vacuum forming, embossing, lamination and printing.

|

Electrical properties

It has high dielectric strength,insulation to high frequencies. and excellent in electrical properties

|

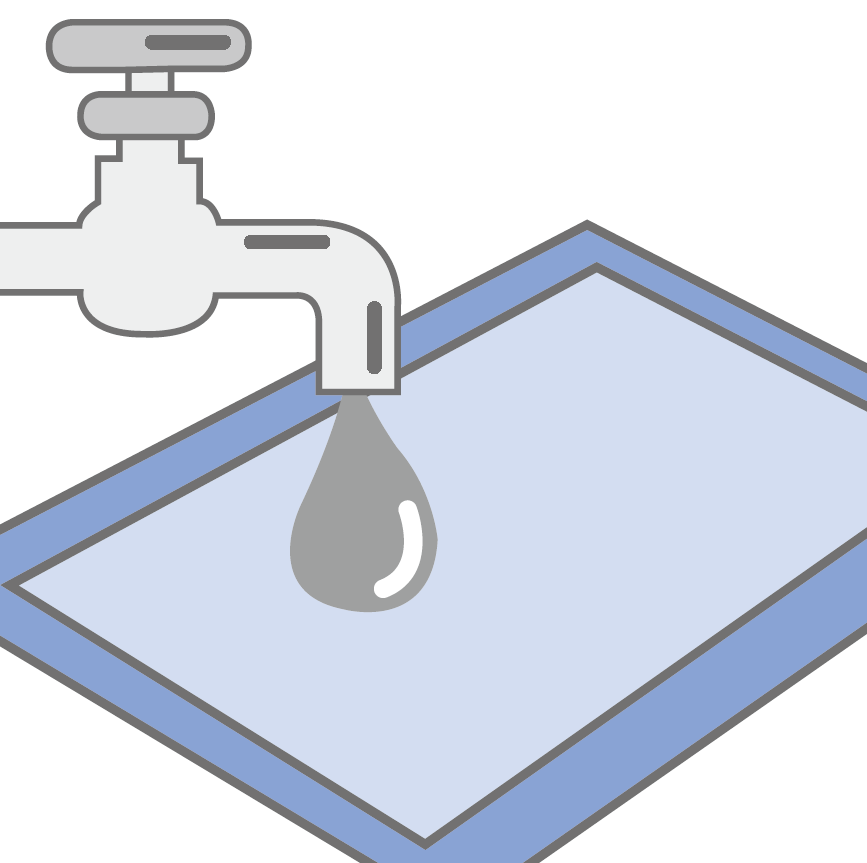

Water resistance

Even if it is left soaked in water for a long time, it absorbs little water.

|

Toughness

It has high mechanical strength, including tensile, tear and compressive strength.

|

Smoothness

With its uniformly sized and fine cells, it feels very smooth.

|

Insulation

It achieves great insulation because it does not allow the air to convect in each cell,

|

Buoyancy

Fine cells are uniformly arranged in this product, which prevents water from penetrating and makes it float in water or other fluid.

|

Light weight

It achieves light weight while keeping high mechanical strength for a foam product.

|

Sealing performance

Softlon achieves excellent flexibility and high adhesion, absorbs little water and demonstrates excellent waterproof performance.

|

Flexibility(Shock-absorbing properties)

It has both elasticity, one of the characteristics of a cell structure, and flexibility , one of the characteristics of polyolefin.

|

|

|

Specifications

Softlon S has intermediate nature between the nature of soft urethane foam and that of polystryrene foam.Its shape can be flexibly changed. In addition, it has good tensile strength and flexibility, and achieves high elasticity, which relieves the feeling of pushing the bottom.

■Comparison of flexibility (Shock-absorbing properties) of Softlon S and other materials

| Item |

Unit

|

Softlon S

(Polyethylene foam)

|

Soft urethane foam

(Ether type)

|

Soft PVC foam

|

Polystyrene foam

|

Cell structure

|

|

Closed

|

Open |

Closed |

Closed |

Thickness

|

mm |

3.00 |

9.84 |

4.82 |

5.20 |

Apparent density

|

kkg/m3 |

33 |

17 |

140 |

32 |

Tensile strength

|

MD |

kPa |

420 |

90 |

980 |

− |

| TD |

290 |

100 |

Elongation

|

MD |

% |

204 |

179 |

111.5 |

− |

| TD |

165 |

212 |

| Compressive strength |

25% |

kPa |

34 |

2.5 |

64 |

240 |

| 50% |

98 |

3.2 |

145 |

307 |

| 75% |

320 |

5.7 |

|

542 |

Compression set

|

|

6.5 |

1.5 |

3.0 |

21.5 |

* Compared with Sekisui's products.

■Comparison of insulation of Softlon S and other materials

Softlon is made of polyolefin, which achieves low thermal conductivity and high insulation.In addition, since it has a closed-cell structure, it absorbs little water and its insulation performance is hardly degraded by moisture. It is also used in a wide variety of fields as an energysaving material with a function of keeping something warm and cool.

|

Density (kg/m3) |

Thermal conductivity (W/m・K) |

| Softlon S |

33

|

0.0343

|

Soft urethane foam

|

25 |

0.0372 |

Rigid urethane foam

|

25 〜35

|

0.0342 〜0.0582 |

Polystyrene foam

|

16 〜30

|

0.0302 〜0.0360 |

Glass wool

|

10

|

0.0395 |

* Compared with Sekisui's products.Data are only references ; they are not guaranteed values.Data are only references ; they are not guaranteed values.

Click here for product details

This is a foamed product which achieves an ideal balance of flexibility, smoothness, heat insulation, and sealing. Various kinds of Softlon S, whose expansion ratio is from 5times to 40times, can be selected according to customer needs.

Features

The standard type with all the Softlon's basic functions.

Eco-friendly

Among resins for foam products, polyolefin is known to be environmentally friendly.

|

Chemical resistance

It isunsusceptible to chemi cals such as acid, alkali and organic solvents. thanks to its resistance to them.

|

Thermal plasticity

It has the features of being stable form at normal room temperature and getting soft so as to be easily molded. when heated.

|

Workability

It responds to various processing methods such as slicing, vacuum forming, embossing, lamination and printing.

|

Electrical properties

It has high dielectric strength,insulation to high frequencies. and excellent in electrical properties

|

Water resistance

Even if it is left soaked in water for a long time, it absorbs little water.

|

Toughness

It has high mechanical strength, including tensile, tear and compressive strength.

|

Smoothness

With its uniformly sized and fine cells, it feels very smooth.

|

Insulation

It achieves great insulation because it does not allow the air to convect in each cell,

|

Buoyancy

Fine cells are uniformly arranged in this product, which prevents water from penetrating and makes it float in water or other fluid.

|

Light weight

It achieves light weight while keeping high mechanical strength for a foam product.

|

Sealing performance

Softlon achieves excellent flexibility and high adhesion, absorbs little water and demonstrates excellent waterproof performance.

|

Flexibility(Shock-absorbing properties)

It has both elasticity, one of the characteristics of a cell structure, and flexibility , one of the characteristics of polyolefin.

|

|

|

Specifications

Softlon S has intermediate nature between the nature of soft urethane foam and that of polystryrene foam.Its shape can be flexibly changed. In addition, it has good tensile strength and flexibility, and achieves high elasticity, which relieves the feeling of pushing the bottom.

■Comparison of flexibility (Shock-absorbing properties) of Softlon S and other materials

| Item |

Unit

|

Softlon S

(Polyethylene foam)

|

Soft urethane foam

(Ether type)

|

Soft PVC foam

|

Polystyrene foam

|

Cell structure

|

|

Closed

|

Open |

Closed |

Closed |

Thickness

|

mm |

3.00 |

9.84 |

4.82 |

5.20 |

Apparent density

|

kkg/m3 |

33 |

17 |

140 |

32 |

Tensile strength

|

MD |

kPa |

420 |

90 |

980 |

− |

| TD |

290 |

100 |

Elongation

|

MD |

% |

204 |

179 |

111.5 |

− |

| TD |

165 |

212 |

| Compressive strength |

25% |

kPa |

34 |

2.5 |

64 |

240 |

| 50% |

98 |

3.2 |

145 |

307 |

| 75% |

320 |

5.7 |

|

542 |

Compression set

|

|

6.5 |

1.5 |

3.0 |

21.5 |

* Compared with Sekisui's products.

■Comparison of insulation of Softlon S and other materials

Softlon is made of polyolefin, which achieves low thermal conductivity and high insulation.In addition, since it has a closed-cell structure, it absorbs little water and its insulation performance is hardly degraded by moisture. It is also used in a wide variety of fields as an energysaving material with a function of keeping something warm and cool.

|

Density (kg/m3) |

Thermal conductivity (W/m・K) |

| Softlon S |

33

|

0.0343

|

Soft urethane foam

|

25 |

0.0372 |

Rigid urethane foam

|

25 〜35

|

0.0342 〜0.0582 |

Polystyrene foam

|

16 〜30

|

0.0302 〜0.0360 |

Glass wool

|

10

|

0.0395 |

* Compared with Sekisui's products.Data are only references ; they are not guaranteed values.Data are only references ; they are not guaranteed values.

Click here for product details