Search by Issue or Need

- Safety(ADAS)

- Environment

- Design / Comfort

Sekisui Mobility Solution

- Safety(ADAS)-

The SEKISUI CHEMICAL Group provides materials that contribute to improving the reliability of ADAS devices, especially the bonding, heat dissipation, and molding technologies we have developed over time.

Challenge

With the evolution of ADAS (Advanced Driver-Assistance Systems), vehicles are being equipped with more and more electronic parts that work to achieve driver safety and comfort, and with this, a range of new issues are cropping up.

For example, we need methods to combat heat in order to prevent safety or performance drops due to the heat generated as electronic parts become more advanced and smaller, and to prevent operation errors due to interference from electromagnetic noise. So, there are increasing needs for heat dissipation and electromagnetic shielding in the materials that make up devices. In particular, there is a strong demand that the performance, safety, and reliability of sensors parts such as radars and cameras that detect what is going on inside and outside the vehicle, and the ECU (Electronic Control Unit) that processes and judges information, be upgraded. In addition, the increase in weight with these added parts means that even as vehicle electrification advances, there are impacts on range, so combining these parts with lightness is a key element.

Solution

The SEKISUI CHEMICAL Group provides materials that contribute to improving the reliability of ADAS devices, especially the bonding, heat dissipation, and molding technologies we have developed over time. Our lineup includes greases and sheet-type heat dissipation products that allow cooling for hot parts such as CPUs and GPUs, and housings for millimeter wave radar or in-vehicle cameras, allowing us to offer materials that combine flexibility, insulation, and are siloxane-free. In addition, for thin noise-absorbing materials that use our sputtering technology and injection-molded products that balance heat dissipation with electromagnetic shielding, we have the technologies to lighten materials or parts by replacing the conventional metal or rubber parts. Also, we shall contribute to improving the reliability of ADAS devices through sealing functions using bonding technology and gap control for PCBs (Printed Circuit Board) that are getting thinner through functional microparticles technology.

Product list

A list of 28Safety(ADAS) items within the 28category.

Easy removable foam tape

-

Adhesion

Adhesion

Heat resistant foam tape 5200series

-

Adhesion

Adhesion

Advancell EM - Thermoplastic-expandable microspheres -

-

Gasp forming & adhesion

Gasp forming & adhesion

High-magnification foam mold technology

-

Increased lightness

Increased lightness

Metal Substitute Technology

-

Increased lightness

Increased lightness

UV curing adhesive PhotolecS

-

Adhesion

Adhesion

UV curing adhesive PhotolecB

-

Adhesion

Adhesion

Double-coated adhesive tapes for fluoroplastics FAFB Series

-

Adhesion

Adhesion

Functional fine particles - Micropearl Series -

-

Gasp forming & adhesion

Gasp forming & adhesion

Flame retardant lightweight composite sheet (Under development)

-

Increased lightness

Increased lightness

Softlon FR-ND, Polyethylene electron beam cross-linked foam

-

Increased lightness

Increased lightness

SELFA - high adhesion easy removable UV tape -

-

Adhesion

Adhesion

1-Part Heat-Curable Grease (Under development)

-

Heat dissipation

Heat dissipation

-

Adhesion

Adhesion

UV curing adhesive Photolec E

-

Adhesion

Adhesion

UV curing adhesive Photolec A

-

Adhesion

Adhesion

Millimeter wave absorbing sheet - masa sorb -

-

EMC measures

EMC measures

Solder anisotropic conductive paste - SACP -

-

Gasp forming & adhesion

Gasp forming & adhesion

Functional fine particles - Epowell GP series -

-

Gasp forming & adhesion

Gasp forming & adhesion

-

Adhesion

Adhesion

-

Increased lightness

Increased lightness

Injection molding with thermal-conductive and EMC shielding

-

Heat dissipation

Heat dissipation

-

EMC measures

EMC measures

-

Increased lightness

Increased lightness

Manion HST - high property, high thermal sheet - (Under Development)

-

Heat dissipation

Heat dissipation

Thermal-conductive greases CGW series

-

Heat dissipation

Heat dissipation

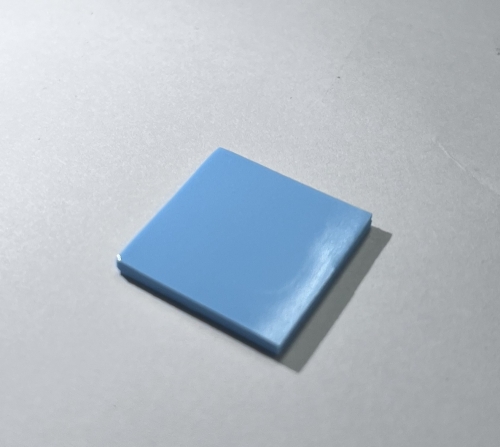

Thermal-Conductive Sheets TIMLIGHT Insulation Series

Insulated High Thermal-conductive, low siloxane silicone heat release sheet

-

Heat dissipation

Heat dissipation

Double-faced adhesive tape 3800 series for fixing LCD components

Double-sided tape for fixing LCD parts

-

Adhesion

Adhesion

Polyvinyl Acetal Resin S-LEC B / S-LEC K

Polyvinyl acetal resin (PVB) with excellent physical properties : Toughness, Adhesiveness and Dispersibility

-

Adhesion

Adhesion

Polyvinyl alcohol Selvol

'SELVOL' is a polyvinyl alcohol resin from Sekisui.

-

Adhesion

Adhesion

Conductive tape 7800 series

Conductive tape

-

EMC measures

EMC measures

-

Adhesion

Adhesion

Products with sputtering technology

Metal spattering technique on fibers( "masa" nano metal coating technique)

-

EMC measures

EMC measures

Water soluble Polyvinyl acetal resin S-LEC KW

'S-LEC KW' is a water-soluble polyvinyl acetal resin with excellent toughness, flexibility, adhesiveness, and dispersibility.

-

Adhesion

Adhesion

Sekisui Mobility Solution

- Environment -

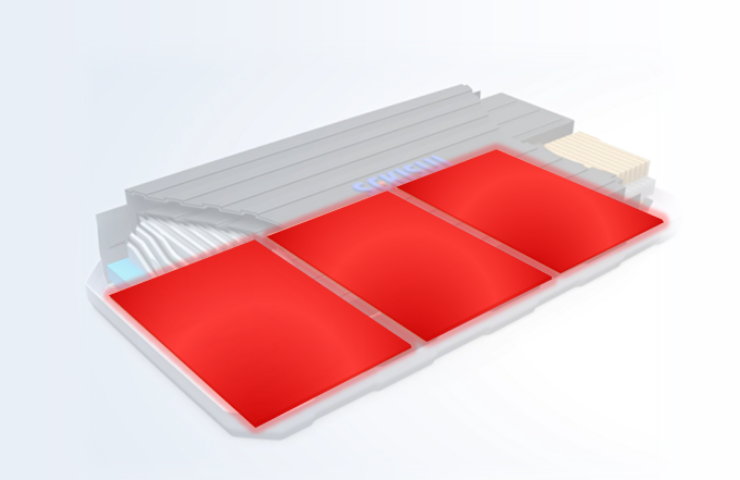

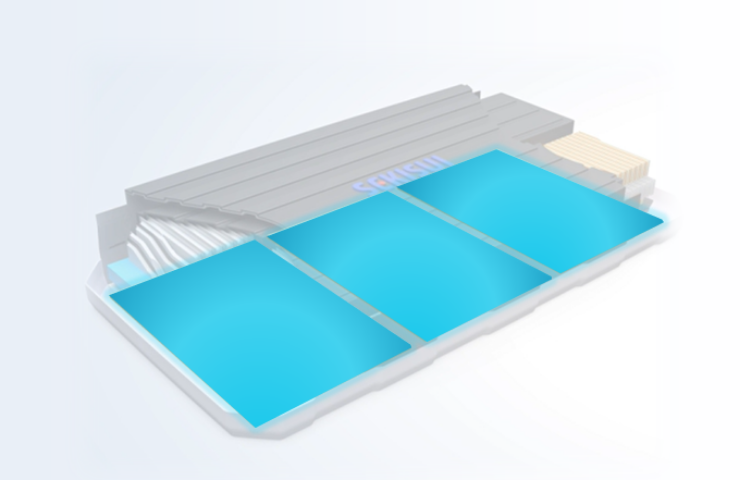

The SEKISUI CHEMICAL Group provides materials that contribute to improving the safety and performance of batteries, especially the bonding, heat dissipation, and molding technologies we have developed over time.

Challenge

Managing battery temperatures is considered important in order to maintain performance stability, safety, and battery life for EVs (electric vehicles).

For example, in low temperatures, the internal resistance of battery cells increases, affecting performance and lifespan, and this may prevent proper charging. In high temperatures, there are effects on output density, causing drops in acceleration performance and thermal runaway, which can damage the battery and cause fires. In addition, to improve the range of EVs, LiB are becoming increasingly higher in capacity, so both lightness and safety need to be balanced. Moreover, there are also the background issues of global warming and the energy problem, so the needs for environmentally-friendly materials for making automobile parts is growing more and more.

Solution

The SEKISUI CHEMICAL Group provides materials that contribute to improving the safety and performance of batteries, especially the bonding, heat dissipation, and molding technologies we have developed over time. For example, in our heat dissipation products, which are well regarded for their reliability when used in EV batteries in Europe, we have a lineup of grease and sheet-type products, and can provide materials that offer flexibility, adhesiveness, low volatility, low density, and so on. In addition, we have technologies that contribute to the safety of battery packs such as shock-absorbing materials that combine low flammability with superior thermal insulation and heat retention properties, fire protection materials that prevent fires from spreading by expanding to create a thermal barrier when a fire breaks out, and thermoplastic resin sheets (currently under development) that combine inflammability, fire retardation, and thermal insulation. In addition, we are working on the development of environmentally-friendly products that use plant-based or recycled raw materials, contributing to the reduction of CO2 emissions.

Product list

A list of 17Environment items within the 17category.

Easy removable foam tape

-

Adhesion

Adhesion

-

Rework

Rework

High-magnification foam mold technology

-

Increased lightness

Increased lightness

Metal Substitute Technology

-

Increased lightness

Increased lightness

Bio-based PET Tape & Foam Tape

-

Adhesion

Adhesion

High heat-resistant tape 5503HT & 5505HR

-

Adhesion

Adhesion

Additive for LiB - PVB Binder Dispersant -

-

Improved battery characteristics

Improved battery characteristics

Flame retardant lightweight composite sheet (Under development)

-

Heatproof / fire retardant

Heatproof / fire retardant

-

Increased lightness

Increased lightness

Softlon FR-ND, Polyethylene electron beam cross-linked foam

-

Increased lightness

Increased lightness

1-Part Heat-Curable Grease (Under development)

-

Heat dissipation

Heat dissipation

-

Adhesion

Adhesion

Millimeter wave absorbing sheet - masa sorb -

-

EMC measures

EMC measures

Injection molding with thermal-conductive and EMC shielding

-

Heat dissipation

Heat dissipation

-

EMC measures

EMC measures

-

Increased lightness

Increased lightness

Manion HST - high property, high thermal sheet - (Under Development)

-

Heat dissipation

Heat dissipation

Thermal-conductive greases CGW series

-

Heat dissipation

Heat dissipation

Thermal-Conductive Sheets TIMLIGHT Insulation Series

Insulated High Thermal-conductive, low siloxane silicone heat release sheet

-

Heat dissipation

Heat dissipation

Products with sputtering technology

Metal spattering technique on fibers( "masa" nano metal coating technique)

-

EMC measures

EMC measures

Engineering adhesives

Solvent-free, low VOC/low odor adhesives developed in Europe and the U.S.

-

Adhesion

Adhesion

Chlorinated PVC resin Sekisui PVC-HA

'PVC-HA' is Sekisui's CPVC resin, which is post-chlorinated special PVC

-

Heatproof / fire retardant

Heatproof / fire retardant

Sekisui Mobility Solution

- Design / Comfort -

The SEKISUI CHEMICAL Group provides materials that contribute to improving the design and comfort of upcoming vehicles, especially the bonding, heat dissipation, and molding technologies we have developed over time.

Challenge

As automated driving evolves, cars are changing from methods of transport to “mobile living rooms.”

At the same time, a lot of systems need to be installed to achieve automated driving, such as ADAS (Advanced Driver-Assistance Systems) and HMI (Human-Machine Interface). These need to immediately present information to the driver during an emergency, and encourage both safe and smooth operations. For that reason, designs that seamlessly blend HMI and conventional interior décor are required in order to balance both safety and the comfort of your living room. In addition, with the reduction of CO2 emissions as a way to counter global warming being a global issue, the shift to EVs (electric vehicles) is moving rapidly. Even as we pursue lightness to increase range, there is an increasing need for materials that can create a sense of high class and comfort through senses other than sight, such as touch.

Solution

The SEKISUI CHEMICAL Group provides materials that contribute to improving the design and comfort of upcoming vehicles, especially the bonding, heat dissipation, and molding technologies we have developed over time.

For example, interlayer films for laminated glass do not stop at just preventing glass from shattering, their core conventional function, but now allow a range of colored designs to be applied. "In addition, combinations of different solutions such as sound deadening or thermal insulation, or wedge-shaped interlayer films for head-up displays (HUD) contribute to the comfort and safe of vehicle interiors. Capacitive touch sensors can respond to a variety of input methods, and allow both designs to be applied and 3D-forming. We are developing a foam that can give a pleasant feel without ruining light displays which will improve the added value of conventional interior cushioning materials, and through combinations of these technologies, we can offer new display designs. In addition, we are moving ahead with proposals to improve the comfort of vehicle interiors and improve the reliability of next-generation HMI devices through increasing the functionality of bonded materials by adding low-odor, low-VOC and high heat resistance as well as increased lightness and improved design by drawing on sputtering technology and injection molding technology.

Product list

A list of 40Design / Comfort items within the 40category.

Polyethylene electron beam cross-linked foam Softlon S

Closed-cell polyolefin materia produced by emitting electron beams to polyethylene, heating and foaming

-

Increased lightness

Increased lightness

Easy removable foam tape

-

Adhesion

Adhesion

-

Rework

Rework

Heat resistant foam tape 5200series

-

Adhesion

Adhesion

Advancell EM - Thermoplastic-expandable microspheres -

-

Gasp forming & adhesion

Gasp forming & adhesion

High-magnification foam mold technology

-

Increased lightness

Increased lightness

Metal Substitute Technology

-

Improved designability

Improved designability

-

Increased lightness

Increased lightness

S-LEC™ Solar Control Film (Heat&UV Isolation Foil)

-

Sound insulation / heat insulation

Sound insulation / heat insulation

S-LEC™ Sound Acoustic Film

-

Sound insulation / heat insulation

Sound insulation / heat insulation

S-LEC™ Wedge Shaped Film

-

Improved HMI functionality

Improved HMI functionality

-

Sound insulation / heat insulation

Sound insulation / heat insulation

Translucent Foam Laminate

-

Improved designability

Improved designability

-

Improved HMI functionality

Improved HMI functionality

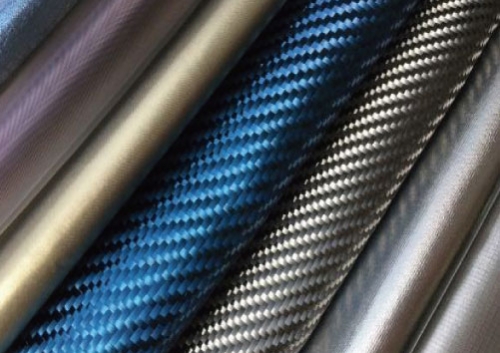

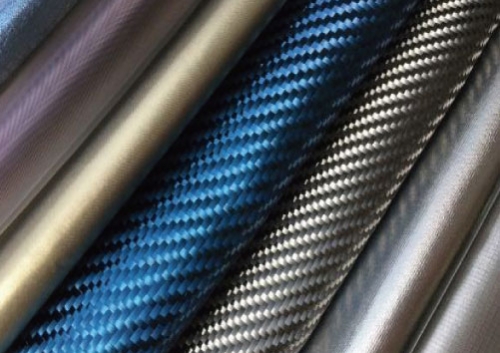

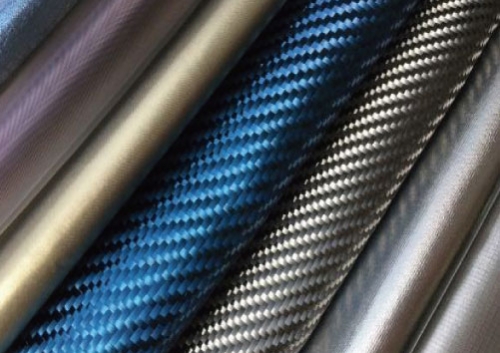

Colour Carbon - AURORADE® -

-

Improved designability

Improved designability

Double-coated adhesive tapes for fluoroplastics FAFB Series

-

Adhesion

Adhesion

Functional fine particles - Micropearl Series -

-

Gasp forming & adhesion

Gasp forming & adhesion

Film-in-mold Technology

-

Increased lightness

Increased lightness

-

Improved designability

Improved designability

PC Injection Molding

-

Improved designability

Improved designability

-

Increased lightness

Increased lightness

Touch sensitive sensor

-

Improved HMI functionality

Improved HMI functionality

S-LEC™ Design Film

-

Improved designability

Improved designability

-

Sound insulation / heat insulation

Sound insulation / heat insulation

Bio-based PET Tape & Foam Tape

-

Adhesion

Adhesion

High heat-resistant tape 5503HT & 5505HR

-

Adhesion

Adhesion

SELFA - high adhesion easy removable UV tape -

-

Adhesion

Adhesion

1-Part Heat-Curable Grease (Under development)

-

Adhesion

Adhesion

UV curing adhesive Photolec E

-

Adhesion

Adhesion

UV curing adhesive Photolec A

-

Adhesion

Adhesion

Millimeter wave absorbing sheet - masa sorb -

-

EMC measures

EMC measures

Solder anisotropic conductive paste - SACP -

-

Gasp forming & adhesion

Gasp forming & adhesion

Functional fine particles - Epowell GP series -

-

Increased lightness

Increased lightness

-

Adhesion

Adhesion

-

Gasp forming & adhesion

Gasp forming & adhesion

Injection molding with thermal-conductive and EMC shielding

-

Increased lightness

Increased lightness

-

EMC measures

EMC measures

Polypropylene electron beam cross-linked foam Softlon SP

PP foam with improved heat resistance and rigidity, suitable as a material for vehicle parts

-

Increased lightness

Increased lightness

Polyethylene electron beam cross-linked foam Softlon IF

Flexible foam with improved expandability and stiffness

-

Increased lightness

Increased lightness

Anti-plasticizer Double-faced Tape 577SA-L

-

Adhesion

Adhesion

Heat Insulation Foam(Softlon NF)

Foam superior in heat resistance and thermoformability, suitable for use in high-temperature environments

-

Increased lightness

Increased lightness

Double-faced adhesive tape 3800 series for fixing LCD components

Double-sided tape for fixing LCD parts

-

Adhesion

Adhesion

Automobile interior and exterior parts

Injection molding products for automotive interior and exterior parts

-

Improved designability

Improved designability

-

Increased lightness

Increased lightness

Double-faced Foam Tape 517TF & 518TF

-

Adhesion

Adhesion

Single-faced tapes for bonding wiring harnesses 735A & 9001EP

-

Adhesion

Adhesion

Double-faced Tape for Oily Surface Tacking 586 & 584

-

Adhesion

Adhesion

SEKISUI 5782 series

-

Adhesion

Adhesion

Products with sputtering technology

Metal spattering technique on fibers( "masa" nano metal coating technique)

-

EMC measures

EMC measures

Engineering adhesives

Solvent-free, low VOC/low odor adhesives developed in Europe and the U.S.

-

Adhesion

Adhesion

Antivirus processing agent Viru-taker

This product absorbs viruses and prevents spread of them !

-

Other

Other